The present report is the result of processing of all available statistical sources relating to the development of prices of solid fuels for household. there are monitored price indicators of graded types of coal and coke, lignite, peat and wood briquettes, wood and vegetable pellets and firewood.

Archiv článků od 5.9.2011 do 5.12.2011

Quality product is dependent on reliable and serviceable manufacturing facility, which is influenced by effective and timely performed maintenance. In order to check the operating parameters it is possible to use vibrodiagnostics, tribodiagnostics, termodiagnostics, non-destructive testing methods and others. It's difficult to choose the right moment to implement maintenance inspection in order to exploit the whole equipment life time and reduced risk of breakdown failure. The fundamental rules for determining the maintenance measurement interval in the diagnostic management system has not been established. Therefore, the emphasis is on determining the interval for measuring of the implementation of periodic data collection, which is more often used than the on-line diagnostic systems for secondary production techniques and technologies with a parallel backup. Proposal for a definition of the calculation of interval measurement is based on the assumption that the calculation must reproduce the behavior of the measured variables and dynamically respond to changes in the trend of damage. Technology has been chosen with a sufficient history of operations and maintenance, to check whether the model of the calculation of the dynamic range of measurement is usable in engineering practice and if it is sufficient enough be to manage and plan the maintenance action. To verify the model five pumps with three parallel backups were used. A major finding from these results is the fact that under the dynamic interval only four more measurements were made than if the measurements were carried out at regular intervals. Just the last four measurements before the outage was made within 31 days, which would normally correspond to one measurement interval. On the other hand, it is necessary under the regular intervals to verify the step change of measured values. This difference in the number of measurements compensated in practice is usually equal to the number of measurements in dynamic mode interval. If based on the premise that the number of measurements under the dynamic range is the same as at regular intervals and use this method in this direction "zero cost" essential contribution is primarily the cost savings on storage of spare parts and reduce the likelihood of other costs with overtime up to 60% compared with measurements carried out at regular intervals. Undeniable contribution to maintenance is also a fact that by making a service action with the deployment of dynamic range measurements, it can even closer determine real life time of bearing and it is possible to use of the maximum potential production of equipment.

The article discusses the development of a test circuit for measuring hydraulic properties of thermal units of building services. The purpose of the test circuit is mainly determining the pressure loss of heat units. First, the article provided the theoretical foundations of the problem. It is also described development of equipment and its function. End of the article deals with the measurement using the circuit and presents the results of measurements.

The article is the result of surveys conducted in the work of raw material and energy department statistics, the Ministry of Industry and Trade. Material published in August 2011 includes data on molded (formed) fuels (briquettes and pellets) made from biomass (wood and plant), peat, coal and paper.

After the implementation of energy saving measures (insulation, replacement windows, hydraulic regulation of heating, etc.) the energy consumption will reduce on the calculated level at which will hold a few years. Evaluation of ENCON projects has found that after 1 year to 2 years energy consumption will rise again.

The heating period 2010/2011 in Prague based on the observation of Prague-Karlov station was 219 days, a little shorter, and with an average temperature of 4.8 ° C, slightly warmer than the long-term average. The basic characteristic of heat demand for heating is 3114 D ° (19) degree days, heat demand is somewhat lower than the long-term average of 3227 D ° (19).

Department of raw material and energy statistics of the Ministry of Industry and Trade dealt with detection rates of solid fuels in 2009, especially briquettes and pellets, under which in December 2010 issued material with the statistical evaluation of items: wood and plant pellets, wood, plant, paper, coal and peat briquettes.

In relation with the present discussions on the use of solar energy it is useful to mention one important stage of Czech agriculture - the production of really high-quality roughage. Besides the development of methods of silage and haylage, thirty years ago the researchers looked at final drying of forage in large-scale haylofts using air solar collectors.

The paper deals with identifying suitable areas of use of small cogeneration units fossil fuels and renewable energy sources in municipal and industrial uses. Discusses the advantages and disadvantages of cogeneration units based on internal combustion engines, gas turbines and steam engines, including their position in the electricity grid

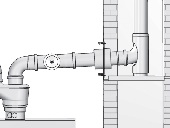

The following article is an excerpt of information from the Czech standard CSN 73 4201 Chimneys and connecting flue pipes - Design, construction and instalation of heatings appliances - about designing single-layer chimney, multilayer chimney, pressurized and high pressurized chimneys, chimney and air vents.

zpět na aktuální články