In today's systems are often also used reflective film. Let us below focus on the physical principle and experimental results. We were interested in saving heat, differences in thermal performance and time to achieve operational status.

Archiv článků od 22.6.2015 do 2.11.2015

The last time we meet with the requirement to improve energy efficiency practically every step, as a result of the implementation of Directive 2012/27/EU into our legislation. The purpose of this regulation is to cause such changes in society and in the energy sector to increase energy efficiency in 2020 by 20% and created the conditions for its further growth in the longer term. The most important area in terms of energy consumption includes heating of buildings.

Owners of residential buildings and their tenants must ensure the implementation of some activities on the technical and fire safety devices in order to ensure their safety and functionality in use. Inspections and checks are therefore not just binding on the applicable regulations, but also may prevent damage to health and property.

The article deals with the change of the basic standard for flue gas of heating appliances. It draws attention to the illegality of technically unjustified distances between flue outlets on the facade and windows or other building openings. The specified distances lead to practical ban on installation of considerably cheaper gas boilers with the flue gas outlet through the facade.

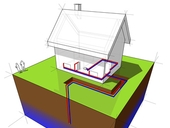

Application of heat pumps in particular water heating and space heating systems for buildings is evaluated by seasonal coefficient of performance determined by calculation procedure based on the design or from the field monitoring of installed system. Primary energy ratio PER is used for comparison of heat pump system with another heat generator from the point of non-renewable primary energy as a measure for environmental impact.

At the turn of 2014/2015 were created by Directive 2009/28 / EC and revised. 406/2000 Coll. – evaluation standards for installers of renewable energy sources. Since July 1, 2015, every person installing subsidized facilities using RES is required to have successfully passing a relevant examination. In the case of biomass boilers is a test of professional competence called Plumber for biomass boilers, code in the National Qualifications Framework is no. 36-149-H.

The paper introduces the energy labelling and ecodesign of heat pumps in accordance with the new European legislative requirements for water and space heaters. This text shows the energy labelling in legislation context and it is followed by next two papers which describe the procedures of heat pumps evaluation for energy labelling in more details.

The paper deals with complex solution of heating and economy measures regarding ecology of heat sources and preservation of architectural values of the Volyně college-complex. This solution also includes padding warm and exchange of windows in all complexes. New technology in boiled room was installed with application of boiler for fytomass-burning, gas condensation boilers, thermal pump in system air/water and cogeneration unit for supply electric energy.

The article presents a new condensing boiler with an automatic feeding system and a burner designed for combustion of biomass with high water content. The boiler has a modular layout allowing great variability in arrangement and performance. Heat output of the boiler can vary within the range from 10 to 500 kW. A stand-alone condensation heat exchanger which is essential part of the boiler is designed as self-cleaning without fouling of heat transfer surfaces. The exchanger’s contribution to overall heat output is about 10 % when combusting wood chips with moisture exceeding 40 %.

The paper focuses on evaluation of heating system with air-source heat pump by bin method. Main goal of the article is to compare obtained results by evaluating heating system in family house with different temperatures of heating water and different temperatures of hot domestic water. The goal is to find out electricity consumption from a grid. The energy demand for heating and hot domestic water preparation is balanced in each interval. The evaluation was calculated with Prague Ruzyne outside air temperature data.

Small boilers are sources of various kinds of pollutants. Nowadays the emission and efficiency limits are given by European technical standards and national directives. New directive of European committee comes with limits for emissions and efficiency which must be met by all small boilers sold after 1. 1. 2020 on European market. Meeting of these limits will be probably attended by higher price of boilers. Article shows the comparison of emission limits for different types of boilers.

Article freely continues the theme of thermodynamic analysis of phenomena occurring in and around the pipeline construction, located in the sandy backfill, now with respect to theoretical foundations, describing the related effects of heat transfer. The article includes in particular the currently known insights into heat exchange in the case where the thermally insulated pipes placed near each other in the soil backfill. Individual processes intended to evaluate size of heat loss are used in the model calculation example a specific pipeline, whose real insulating state has previously been verified by measurement.

zpět na aktuální články